The current energy and climate challenges require energy conversion systems that are more efficient and make use of renewable sources of energy. A power generation system that has been envisaged to considerably increase the thermal to electric conversion efficiency is the Brayton cycle with supercritical carbon dioxide (s-CO2) as the working fluid. The technical developments required to realize such novel thermal power plants are mainly related to the materials used and the design of the components due to the high temperature and pressure of the working fluid: 850 °C and 250 bar at the turbine inlet in order to reach 55.8% thermal efficiency. Many organizations have been working on this development and there is high interest in Europe to bring the technology forward in order to meet its energy policy goals.

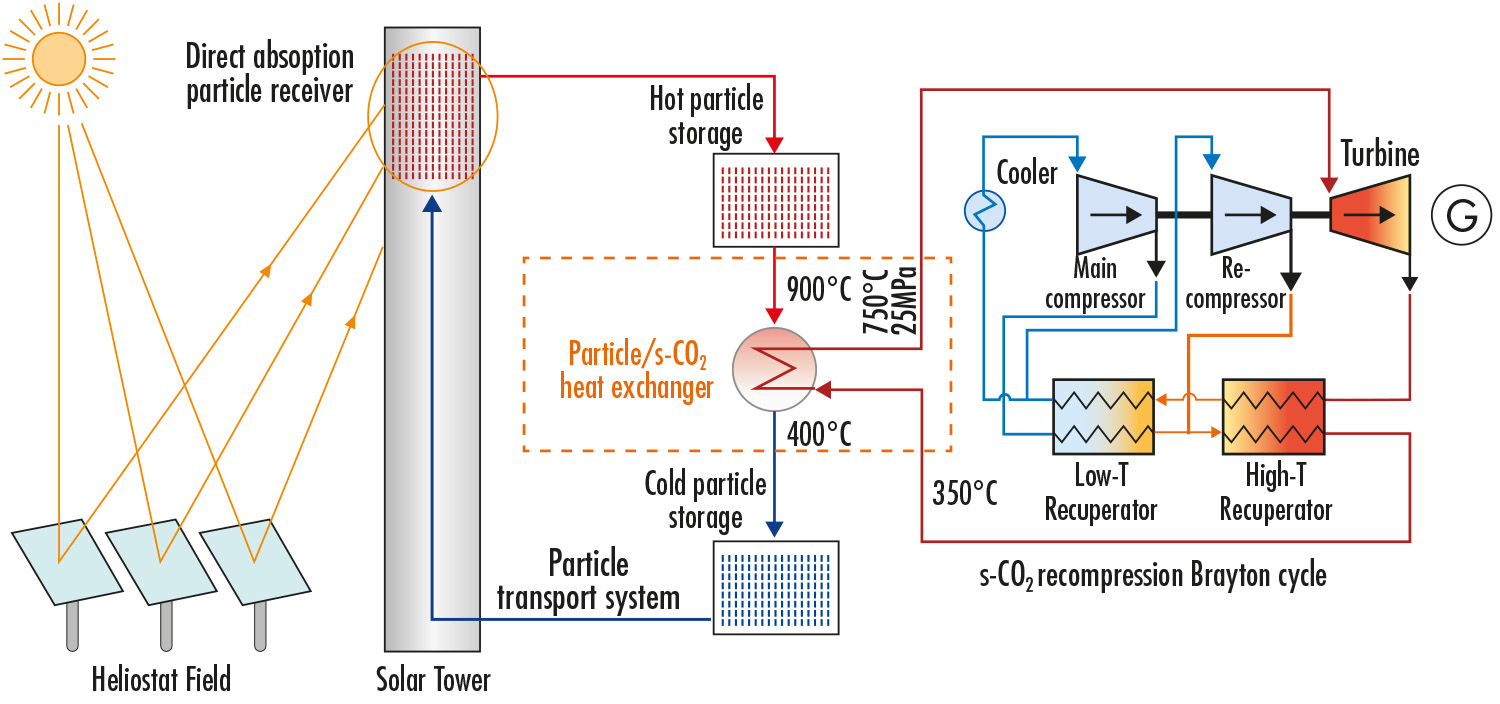

The focus of COMPASsCO2 is on the efficient and reliable integration of storable solar energy provided by concentrated solar power (CSP) systems into the s-CO2 Brayton cycle.

Current state-of-the-art for CSP technologies is the use of solar towers with molten salt receivers, in which “solar salt”, a mixture of 60% NaNO3 and 40% KNO3, is heated from 290°C to 565°C and a steam turbine (Rankine Cycle) is driven to produce electrical power.

State-of-the-art bauxite particles. Source : DLR

Currently, the research focus regarding CSP technology is mainly related to the development of systems that can reach higher temperatures than those currently applied on commercial plants (390°C for thermo-oil and 560°C for molten salt). Higher heat transfer medium temperatures allow the connection of solar energy into highly efficient and/or innovative systems such as “solar fuels”, material production (e.g. aluminium recycling), solar water treatment, sea water desalination and synthesis of chemicals. Two media are investigated to allow temperatures of 1000 °C or more: air and solid particles. Of these, solid particles have the advantage over air that they can be directly used as the thermal storage media, reducing the complexity of the systems and therefore the costs. On the other side, solid particle systems impose challenges to the materials due to their high temperatures and abrasion effect.

COMPASsCO2 project looks specifically at material and lifetime aspects of the particles and the metals being in contact with them, and at validating a particle/s-CO2 heat exchanger.

COMPASsCO2 opens the path for a future commercial application of solar s-CO2 Brayton cycle with the development of novel materials and components specifically designed for the linkage of the solar/storage system with power cycle via a particles / s-CO2 heat exchanger. This requires the joint research effort of CSP and material researchers as well and industrial components manufacturer specialists.